In the framework of the valorization of its research, CESI makes its expertise and platforms available to companies and accompanies them in their innovation processes: diagnosis, consultancy, recommendations, improvement of internal processes, management, training, skills transfer.

Thus, we propose, in the fields of innovation, additive metal manufacturing and technologies of industry 4.0 or of intelligent and sustainable city :

- The assistance of our experts on R&D projects,

- Access to our technological platforms,

- Methodological support for innovation,

- Skills transfer through customized expert training,

- Realization of parts and prototypes.

In addition to direct services, we also offer the implementation of collaborative research projects, the development of teaching and research chairs or support for so-called CIFRE (industrial) theses.

Transfer and valorisation are dealt with by the folllowing people :

Platform MAM – Nanterre

- Jean-Daniel Penot (Associated teacher-researcher, in charge of the MAM activity)

- Lucas Reyes (research engineer)

Platforms Industry of the Future and Building of the Future – Nanterre

- Aline Becq (research engineer)

- Sébastien Monier (research engineer)

- Nicolas Duhamel (research technician)

Plateform Industry of the Future – Rouen

- Fabrice Duval (Teacher-researcher – entitled to supervise research)

- Nicolas Briant (research engineer)

Our expertise and offer in Metal Additive Manufacturing (MAM)

Additive manufacturing, or 3D printing, is one of the key technologies of the industry of the future. In just a few years, it has become widely used in various industrial sectors such as medical, space, automotive, aeronautics and many others.

Learn more

Additive manufacturing refers to a set of processes that allow a part to be manufactured by superimposing successive layers of material, based on a virtually sliced digital model (CAD).

The most promising additive metal fabrication processes are laser fusion of metal powders. This technology proves to be particularly suitable for single parts or small series at a reasonable cost. It offers a fabulous freedom of design and conception.

It allows the creation of complex, ultra-customized parts with high added value. In the industry, the growth of additive manufacturing is bringing about a profound paradigm shift.

In just a few years, this technology has begun an upheaval in the manufacturing methods and processes of several cutting-edge industries, such as the medical equipment industry. Today, a growing number of companies are seeking to position themselves in additive manufacturing.

Aware of the stakes of these new manufacturing processes for the industry, CESI optimizes the skills upgrading of its learners by fully integrating this future technology in its training offer: in particular the option “Additive Metallic Manufacturing” proposed in the engineering cycle of the School. In order to train its students in the best possible way, CESI has acquired its own metal additive manufacturing unit in powder bed technology, installed on the Nanterre campus.

Based on our research work on the process and innovative design for additive manufacturing (ANR CREAM project), we offer high level services to companies:

- Support for the industrial integration of the MAM : decision support, project management assistance, support on HSE aspects, development of dedicated environments,

- Raising skills through training in inter enterprise modality on : innovative design for the AM (exclusive methodology); production start-up; control of industrial and environmental risk; the keys to successful industrial integration of the MAM,

- R&D projects : assistance in designing innovative parts that fully exploit the strengths of the AM, opportunity studies,

- Pooling of the additive manufacturing platform : access to technological means, manufacturing of prototypes and pre-series (maraging steel, titanium, polymers).

Our technological means in AM :

- Form Up 350 Printer

- Markforge Metal X

- Markforge Two (composites)

- Scanner Emetec HandyScan 700

Expertise in Management of the culture of innovation

From a macroeconomic perspective, there is consensus on the need for innovation. In France, organizations focus their innovation efforts primarily on R&D, while other strategies are more effective. This situation may be linked to the nature of indicators and incentives for innovation, which focus on investment made rather than on performance.

Learn more

To innovate, a recent trend suggests developing a favorable culture.

Our work has led us to propose a model of innovation culture in organizations, structured around five dimensions. The first three dimensions refer to the human dimension: managers, teams and innovative individuals. The other two are more philosophical in nature: on the one hand, the favorable organizational context, and on the other hand, the multiplicity and ease of relations with the environment.

Based on recent research work that has enabled us to develop tools and methods, we propose to support companies in the dissemination of a high-performance innovation culture:

- Realization of a diagnosis and a precise identification of brakes and levers,

- Definition of the target culture in line with the company’s development strategy,

- Assistance to the company in the implementation of transformation processes aimed at increasing the commitment of the teams,

- Measurement of effectiveness, effects and evolution over time.

The modalities proposed are various: consulting services, collaborative research programs, support for industrial (so-called CIFRE) theses

Expertise in product innovation and prototyping

There are three main innovation strategies: Technology Driver, Market Reader and Need Seeker. The latter is based on the anticipation of future market needs and future uses: innovation observatories around the world suggest that this strategy is the most effective in terms of innovation today. However, the majority of French companies are still structured according to a Technology Driver strategy focused on R&D.

Learn more

Our researchers have developed new methods to help companies structure their Need Seeker approach, the most effective.

These methods have been validated in the field, in the context of collaborations with companies, particularly SMEs, and thus contribute to fostering their growth through innovation.

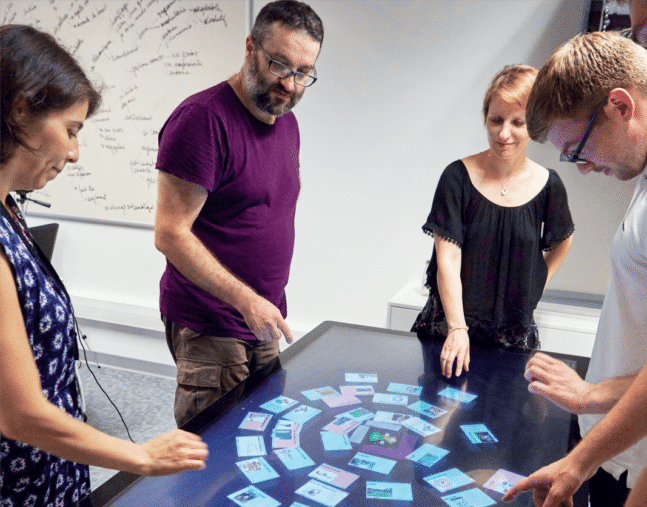

In support of this assistance to innovation projects, CESI proposes to use its creativity, innovation and prototyping laboratories in the framework of seminars for project or marketing teams for example, to develop new ideas or new products and services. Finally, partner companies can realize or entrust us with the realization of product prototypes (technical tests and improvements, validations, user and marketing tests).

Our service offer in innovation and prototyping is as follows :

- User-centered approach, from the discovery of needs to the evaluation of solutions,

- Assistance “from the idea to the realization” of innovative products and services,

- Training : creativity methods, discovery and creation of needs, user experience, project management through innovation,

- Realization of prototypes within our Lab’CESI.

- Provision of our innovation laboratories and our Lab’CESI and/or animation of creativity seminars within them.