Technological platforms

CESI LINEACT has state-of-the-art platforms and equipment, as well as a technical team of research engineers and a competent administrative unit to manage them.

Technology Platforms and Partnerships

CESI LINEACT has state-of-the-art platforms and equipment, as well as a technical team of research engineers and a competent administrative unit to manage them. Its strategy of development, maintenance and openness to third parties (competitiveness clusters, industrial sectors, industrial partners) as well as higher education, research and secondary school players is the key to maintaining a high level of quality and performance, while offering opportunities for collaboration and partnership. 12 research engineers are dedicated to the maintenance and operation of these platforms and resources dedicated to research, training and transfer.

The acquisition of these platforms is part of a long-term strategy. They are used both for research and training purposes, and for the direct transfer of new knowledge to local communities, and are maintained to ensure their long-term operability.

The three outstanding research and transfer platforms, “Industry of the Future” at the Rouen and Nanterre campuses, and “Building of the Future” at the Nanterre center, enable research to be deployed and supported by teaching. They are used by both research teams, and are accessible to all lecturers/associate professors and students on the various campuses.

The main technological platforms

CESI LINEACT’s equipment enables it to offer innovative, high-quality solutions for ambitious projects. The main platforms are :

- A platform dedicated to Industry of the future :

The “Industry of the Future” platform, located on the CESI campus in Rouen, reproduces a modular production workshop incorporating an automated production line, industrial manual stations for assembly and quality control operations, AGVs (mobile robots) for transporting parts and products, manipulator robots, cobots for collaborative assembly tasks, IoT for data exchange, and human-machine interfaces based on augmented reality or virtual reality to assist or train assembly or maintenance operations.

This platform is backed up by a digital twin developed as part of the laboratory’s research activities, and is integrated into various educational projects. Applications in CESI LINEACT’s research work, but also in teaching, are in the fields of industrial organization and performance, maintenance, digital technology, AI, cyber-security and, of course, the use of so-called “industry of the future” technologies such as robotics/cobotics, digital twins and AR/VR, the specific resources of which are presented below.

- AR/VR equipment integrated into digital twins

Augmented reality (AR) and virtual reality (VR) are immersive technologies that offer numerous opportunities for research and industry. In research, AR and VR, often coupled with digital twins, are used to simulate complex environments that reduce development costs and times, limit the risk of errors and design flaws, or visualize complex data in an interactive and intuitive environment. These technologies enable research hypotheses to be explored and tested, or professionals to be trained more effectively and interactively, particularly with the advent of Industry 5.0 and the reintegration of humans at the center of industrial processes.

AR and VR are also used for training and simulation in complex industrial environments and hazardous or difficult situations, such as interventions in atex areas (atmosphere at risk of explosion in the presence of an ignition source) for example. Most CESI LINEACT campuses are equipped with headset-type AR/V equipment. One of its campuses is equipped with a dedicated technical platform for collaborative situations with several VR users, a 4-sided CAVE, data acquisition and processing systems to study the behavior of the user in VR.

- A set of robotics platforms being rolled out across the six CESI regions

Initiated by a number of CESI centers, robotics is now in full expansion at CESI, with the arrival of 18 Robots spread across the different campuses. In research, robotics can be used to carry out complex experiments, explore dangerous or inaccessible environments, and develop new technologies and applications. Robotics can be used to improve the efficiency and productivity of manufacturing processes, reduce production costs and times, and enhance product quality. Robots are used in many industrial sectors, such as automotive, aeronautics, electronics, logistics and healthcare, to carry out repetitive, dangerous or high-precision tasks. Robotics also offers great potential for innovation and the development of new applications. Collaborative robots, for example, are robots designed to work alongside humans, opening up new possibilities for task automation in many industrial fields. Robotics platforms can also be used to address themes common to the “Learning and Innovating” and “Engineering and Digital Tools” research teams, notably human-robot interactions.

Additive manufacturing, commonly known as 3D printing, offers many advantages for research. First of all, additive manufacturing enables prototypes to be created quickly and cost-effectively, which is particularly useful in research where trials and tests are often necessary to validate concepts or hypotheses. Additive manufacturing also makes it possible to create complex shapes and structures that would be difficult or impossible to achieve using traditional manufacturing techniques.

Additive manufacturing is an innovative sector, however with a large number of specific features requiring a high level of expertise in order to master the manufacturing and finishing processes. In addition, additive manufacturing offers great flexibility in terms of materials and manufacturing processes, enabling researchers to develop innovative materials and explore new applications. CESI is also equipping this platform with a digital twin.

Additive manufacturing, commonly known as 3D printing, offers many advantages for research. First of all, additive manufacturing enables prototypes to be created quickly and cost-effectively, which is particularly useful in research where trials and tests are often necessary to validate concepts or hypotheses. Additive manufacturing also makes it possible to create complex shapes and structures that would be difficult or impossible to achieve using traditional manufacturing techniques.

Additive manufacturing is an innovative sector, however with a large number of specific features requiring a high level of expertise in order to master the manufacturing and finishing processes. In addition, additive manufacturing offers great flexibility in terms of materials and manufacturing processes, enabling researchers to develop innovative materials and explore new applications. CESI is also equipping this platform with a digital twin.

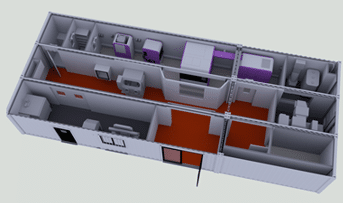

A smart building can provide an advanced infrastructure for real-time data collection, enabling researchers to monitor and measure parameters such as temperature, humidity, light, noise and so on.

This can help improve the accuracy of experiments and reduce experimental errors, validate models or create modeling AI bricks. This platform, located on the CESI campus in Nanterre, also includes a digital twin.

Center HPC DIGITLAB is a private server system specially designed to meet the needs of teaching and research, particularly in the field of artificial intelligence (AI). In recent years, as AI has grown, it has become crucial to be able to carry out heavy processing on GPUs (Graphical Processing Units) or multi-core architectures, particularly for learning tasks. The speed at which such processing can be carried out depends greatly on the performance of the machine on which it is run. Computing power requirements can vary considerably from one researcher to another, from one research work to another, making it difficult to satisfy all demands equally.

The Centre HPC DIGITLAB offers a cost-effective solution precisely to address this reality and the occasional need for heavy-duty processing. Rather than providing dedicated machines for each researcher, Centre HPC DIGITLAB offers a private service based on a cloud model, enabling hardware resources to be shared between users in an optimized way. Researchers can reserve a virtual machine for a fixed period, according to their specific needs, while avoiding the high costs associated with acquiring, maintaining and managing their own infrastructure.

What’s more, Centre HPC DIGITLAB facilitates resource management by enabling allocation according to availability, via a reservation tool developed by CESI’s Information Systems Department. Researchers can thus plan their research work by reserving specific time slots, guaranteeing efficient use of resources and avoiding access conflicts. The allocation of machines will depend on the resources available at the time of reservation. The initial version of Centre HPC DIGITLAB includes three virtual machines dedicated to research, whose use can be adjusted according to utilization rates.

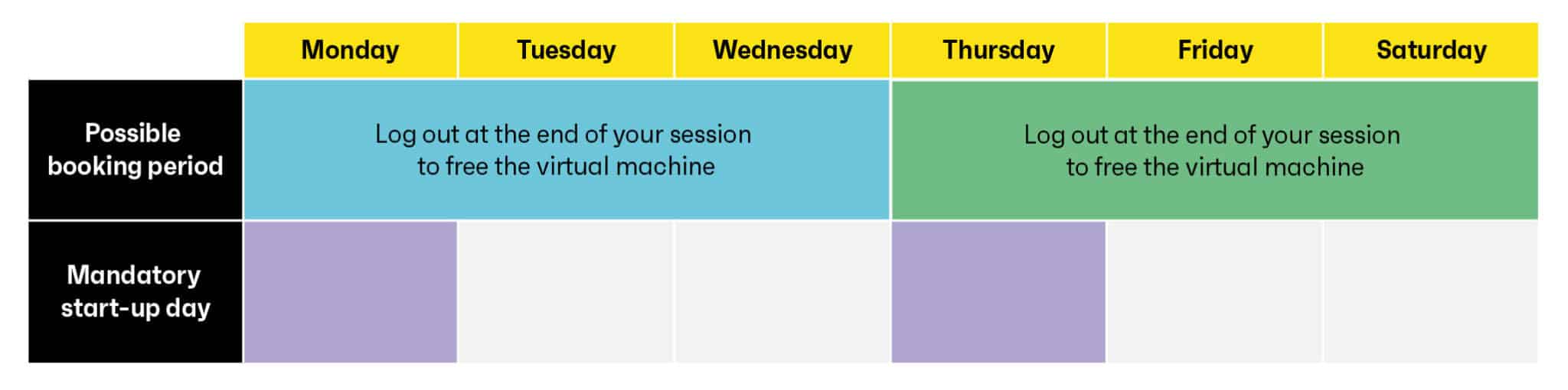

The reservation slots initially planned are as follows

Exploration and Experimentation: CESI LINEACT Platforms at the Service of Innovation and ResearchThe research teams

They enable them to conduct advanced experiments, train complex models, explore new approaches and accelerate their scientific discoveries.

These technology platforms are deployed across CESI LINEACT’s various sites, so that they can be used on a large scale, and their use secured. Funding for the design and deployment of technology platforms is leveraged through APP/AMI calls for projects and expressions of interest, while requiring CESI and CESI LINEACT to make their own investment, which is fully assumed.

Details of three examples of remarkable platforms resulting from this approach:

JENII Project Boosts ‘DemoES’ 2021 Education Initiatives

The JNs developed or optimized as part of the JENII project are among the 17 higher education demonstrators supported by the “DemoES” 2021 future investment program.

digital twins (JNs)

This platform is the result of structuring projects such as the DEFI&Co program. Since 2015, it has enabled the deployment of research activities relating to digital and educational sciences, notably through the design of digital twins (JNs) interfaced in virtual or augmented reality and linked to its research platforms in the fields of industry and construction.

These JN prototypes, combined with CESI LINEACT’s research work on modeling and architectures for JNs interfaced in VR/AR, on instrumented learning environments and their pedagogical integration (NEO-SAI 2019 and 2021 symposium), are recognized in the academic and industrial communities. This work has led to new major projects such as JENII (Jumeaux d’Enseignement Numériques, Immersifs et Interactifs) – ANR-21-DMES-0006. This project will identify and support higher education establishments ready to become demonstrators of all dimensions of the digital transformation affecting our society (pedagogy, equipment, uses…).

With the largest budget (€14 million – €9.5 million grant, €1.75 million for CESI) obtained in this call for expressions of interest, highlighting its strategic and scientific importance, it brings together for the occasion a unique consortium (ENSAM, CNAM, CEA Tech and CESI). Within the framework of this project, which involves 3 PhD students supervised by CESI LINEACT, CESI and CESI LINEACT’s actions focus on developing or improving individualized hybrid and multimodal learning paths, and on R&D, in technological, pedagogical and usage dimensions, on the Digital Twins of the Industry of the Future and Metal Additive Manufacturing platforms.

JENII – The DT (Digital Twins) of the CESI platforms

micro learning factories

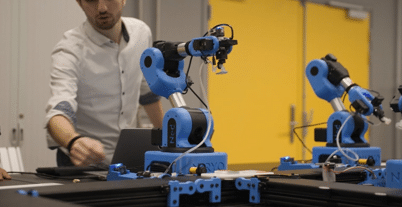

Launched in June 2021, the Micro Learning Factories (MLFs) project aims to deploy, on CESI campuses, platforms dedicated to research and teaching in the fields of robotics, automation and the key technologies associated with these areas: computer vision, connected objects (IoT, M2M), artificial intelligence, digital twins, augmented reality, etc. Structured in three phases, the MLF project has over the period from June to December 2021 (Phase 1 – Expression of needs and Specifications) focused on the specification of requirements for research and educational teaching activities and functional analysis. In the period January to December 2022, the work was devoted to hardware investments (Equipment of 6 CESI campuses, including for each campus: a platform comprising 10 removable tables, 6 6-axis robotic arms, 6 NIRYO conveyors, 5 student laptops, network equipment, a high-performance workstation, a HOLOLENS 2 augmented reality headset. …) and the development of a PoC (Proof of Concept) by a team of associate professors, research engineers and teachers from the Rouen, Arras, Nanterre and Lyon campuses. Since January 2023, the MLFs project has embarked on phase 3 of its roadmap, with the rollout of MLFs platforms to the Toulouse, Arras, Strasbourg and Saint-Nazaire campuses mobilized for the project.

MLFs Project Aims for Full Campus Deployment by December 2023

The MLFs project aims to have the MLFs platforms in production on all the campuses involved in the project (Lyon, Nanterre, Rouen, Arras, Toulouse, Saint-Nazaire and Strasbourg) by December 2023, for engineering courses specializing in general engineering, computer science and embedded electronic systems. The MLFs platforms integrate a wide range of equipment (6-axis robotic arms, conveyors, mobile robots, sensors and actuators, controllers, supervisors, etc.) designed to faithfully reproduce, on a reduced scale, a production system representing an assembly process similar to those used in manufacturing industries. Positioned on the first three levels of the automation pyramid (Level 0: Capture/measure/actuate, Level 1: Control/command/automate, Level 3: Supervise, Level 4: Orchestrate, Level 5: Manage), the equipment on the MLFs platform will make it possible to address educational content targeted at each of these levels, to instil into students knowledge and skills in robotics and automation. Also intended for research and innovation activities, the platforms will be used by associate professors to experiment advanced concepts (autonomous, collaborative, cooperative, decentralized production systems, etc.), test and experimentally validate theoretical models, and popularize and illustrate their robotics research work.

MLF platform : deployed system integrating five 6-axis robotic arms and six conveyors per student in teaching situation

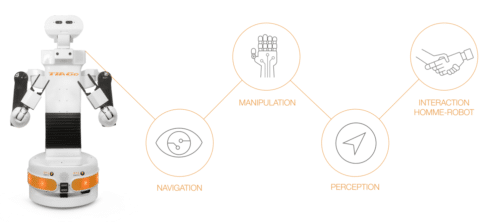

Equipped for Environment Understanding and Human Interaction

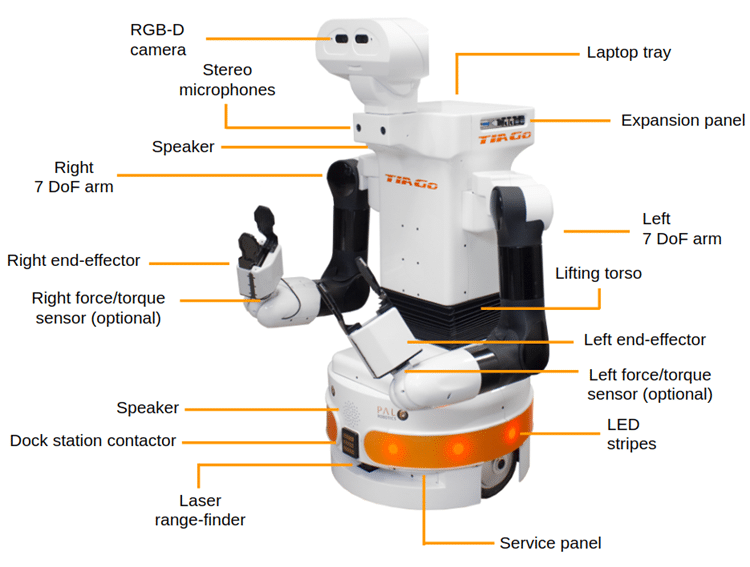

Tiago++ is equipped with a range of sensors enabling it to understand its environment, such as lidar, an RGB-D camera and an arm-mounted camera. To enable it to interact with humans, particularly in the context of Industry 5.0, the Tiago++ robot is equipped with stereo microphones, speakers, a swiveling head, a torso to adapt its stature to the person, an on-board screen on the torso (not shown in the photo), and two robotic arms.

TIAGO++ robots

CESI has acquired its first 6 Tiago++ robots and continues to deploy dual robotic physical environments for teaching and research activities on part of its campuses. The Tiago++ humanoid robot offers multiple advantages for teaching and research. Thanks to its humanoid form, it can interact naturally with students or researchers, thus creating a more engaging learning and collaboration environment. Tiago++ can be programmed to guide students in the acquisition of specific skills, providing clear explanations and practical demonstrations. It will also be used as a research tool, enabling researchers to deepen their research areas and explore new ones.

In addition to its hardware capabilities, the Tiago++ robot comes with a software suite based on ROS (Robot Operating System), enabling research teams to create standardized robotic building blocks that can be shared with the wider scientific community. All its sensors, actuators and software suite make it invaluable for conducting experiments and collecting data in a variety of research and educational contexts. In short, Tiago represents a promising technology that opens up new perspectives in education and research, offering enriching human-robot interactions and innovative exploration opportunities.

Technical coordinators

Technical coordinators with specific mission statements are appointed on each campus benefitting of technology platforms. The technical coordinator is responsible for operating and maintaining the platform. When platforms are deployed on several sites, a project manager is in charge of coordinating the community of technical referents and ensuring the continuous improvement of resources through ongoing technological monitoring. The aim is to continuously adapt the capabilities of the devices for CESI LINEACT’s teaching and research activities, or as part of partnership projects. Technological resources are also used within the framework of engineering and service contracts carried out by the research support teams. CESI LINEACT’s equipment has been acquired in part through project leverage.