Transformation of the training offer and creating new training programs

- Project leader : CESI LINEACT

- Call for Projects: Normandie SUP

- Project Budget: 90.2 k€

- Project Launch: October 1st, 2024

- Project Duration: 12 months

Industry of the Future at the center of Normandy’s Pedagogy

Digital Twin (DT) technologies now represent a major performance lever for modern industries. They offer concrete solutions for the remote operation of robots, enabling both remote technical supervision and the safe manipulation of equipment in hazardous zones.

By coupling these tools with Extended Reality (XR) technologies, CESI is innovating to simplify robotic programming methods and assist operators in their daily tasks. Training future engineers to design and use these digital twins interfaced with XR is a priority: it significantly raises the skill level of graduates in the Normandy region and better meets the industrial needs of tomorrow.

CESI’s implication to Industry 5.0 Strategy

CESI reaffirms its commitment to training engineers capable of enriching the industry of the future by evolving its curricula. Within the Engineering degree specializing in Computer Science, an option dedicated to learning Virtual and Augmented Reality technologies is offered.

Through this ambitious project, CESI LINEACT has developed new educational modules based on mixed reality and digital twins. To make this learning experience concrete, a “JNXR” (Digital Twin & XR) educational demonstrator has been implemented in an industrial context. This platform allows students to engage with the design of real-world solutions, providing a better understanding of the actual needs of businesses.

- Action 1 – Evolving the AR/VR Training Offer with DTXR

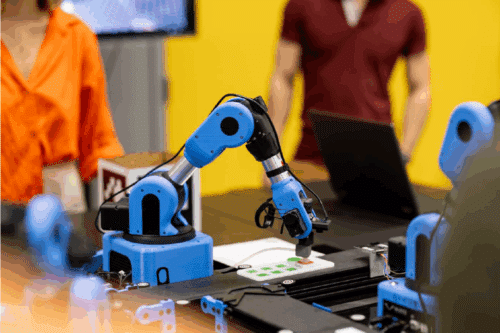

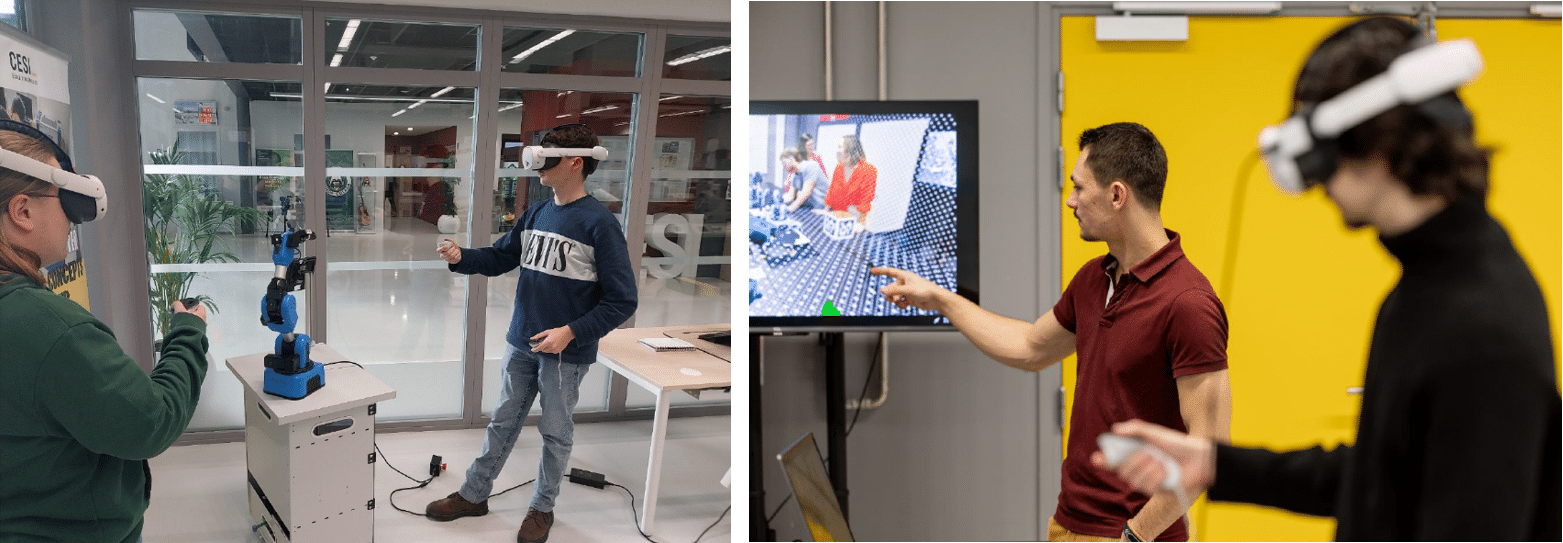

This first phase consisted of introducing the fundamental concepts of Digital Twins through recognized industrial standards, such as OPC-UA and MQTT, within the AR/VR option. The major innovation lies in the control of these systems via mixed reality, using Meta Quest 3 headsets.

Supported by dedicated course materials and Niryo NED 2 training robots, students explore the programmable methods and functionalities of the machines. They learn to develop the application side of the digital twin, ensuring:

- Real-time synchronization of the robot’s states;

- Fluidity of movement between the physical and virtual worlds;

- Optimization of immersive interactions.

This global approach enables students to master the strategic challenges of digital twins in complex industrial environments, turning them into experts capable of enriching the industrial expertise of the region.

- Action 2 – Designing an Educational Demonstrator for JNXR Uses in Industry.

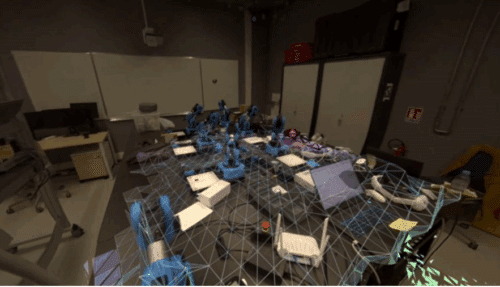

The second action focused on developing a physical and virtual demonstrator to showcase the advantages of Digital Twins through practical examples. This device makes the use of robotics much more accessible and understandable for future engineers, who can experiment on their own projects based on an existing framework.

Based on the MLF (Miniature Learning Factory) and Niryo robots, this demonstrator offers advanced features:

- Immersive Versatility: The ability to switch between virtual reality and mixed/augmented reality depending on the needs of the scenario

- Trajectory Planning: The user defines movements directly on a virtual copy of the robot, superimposed in mixed reality onto the physical robot.

- Secure Validation: Execution on the real robot is only triggered once the trajectory has been validated and simulated numerically.

- Group Collaboration: Visualization within the headset of virtual robots programmed in the Digital Twin, allowing for impact assessment without the risk of damage, all within a collaborative space that fosters fluid and engaging interactions for an entire group of students.

CONCLUSION

Finalized in October 2025, this project is seeing its first concrete applications on the Rouen campus during the AR-VR option training session in late 2025 – early 2026.

This achievement reinforces the recognition of Normandy’s expertise in the field of industrial XR. By integrating concepts of human-machine collaboration and process optimization via versatile robots, CESI is actively participating in the development of Industry 5.0, while maintaining an innovative, engaging, and highly professional pedagogical approach.