NORMANDIE SUP CSTI 3NC

- Project leader: CESI LINEACT

- Call for projects: Normandie SUP

- Total project budget: €463 000

- Project launch: October 1, 2024

- Project duration: 36 months

CESI aims to strengthen and reaffirm its structuring role in the dissemination of scientific, technical and industrial culture (STIC) in Normandy by organizing and expanding its educational workshop offerings and by broadening its network of academic partners. A three-year visibility makes it possible to envisage the design of more ambitious workshops, in line with the developments of Industry 5.0 and emerging technologies such as robotics and human–machine interaction, additive manufacturing, digital twins and XR technologies.

Building on its recognized expertise, CESI carries out numerous scientific outreach and mediation initiatives, notably supported by the RIN ACTION SUP schemes, and plays a leading role within the framework of the “Cordées de la Réussite” program. The campus regularly organizes interactive workshops for middle and high school students and actively participates in events promoting scientific and institutional outreach. These workshops, directly linked to the skills of the laboratory and CESI training programs, offer students concrete immersion in the challenges and professions of the industry of the future.

An evaluation of existing initiatives has highlighted the need to strengthen the immersive dimension of robotics workshops and to better showcase the industrial challenges of additive manufacturing. The integration of virtual reality and dedicated modules for these technologies aims to enrich students’ learning experience, deepen their understanding of key Industry 5.0 technologies, and prepare them for the challenges and opportunities of tomorrow’s industry. To achieve these objectives, we have decided to implement five actions :

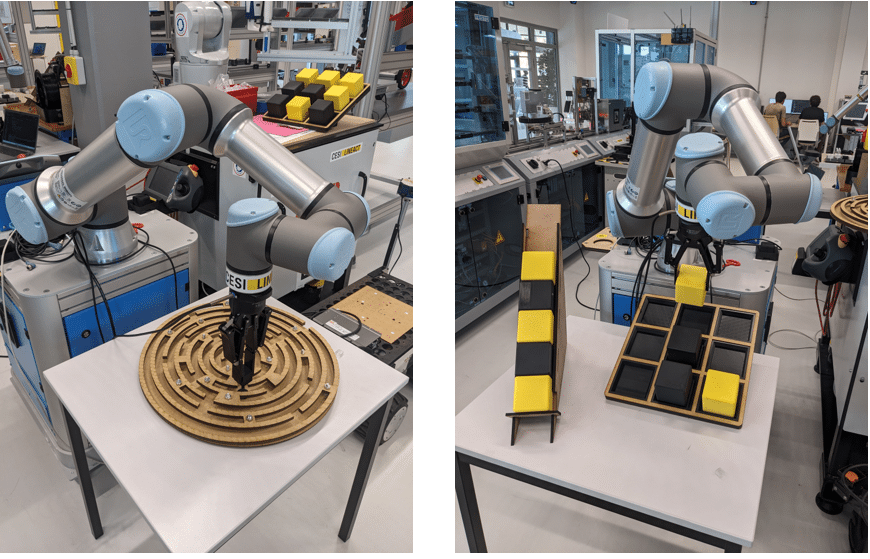

Action 1 – Interactive Robotics Workshop : Exploring Industry 5.0

The current dissemination of scientific, technical and industrial culture within the flexible workshop of the Industry 5.0 demonstrator is mainly based on demonstrations, placing participants in the role of passive observers. However, hands-on learning is an essential complementary approach that fosters engagement, conceptual understanding, the acquisition of practical skills, and the development of abilities such as creativity and problem-solving.

Transforming the workshop into a more interactive format will allow participants to directly manipulate robots, understand how they operate, program them, and integrate them into manufacturing processes. This concrete immersion will provide a better understanding of advanced technologies, industrial process optimization, and the challenges of Industry 5.0, while preparing participants for the manufacturing challenges of tomorrow.

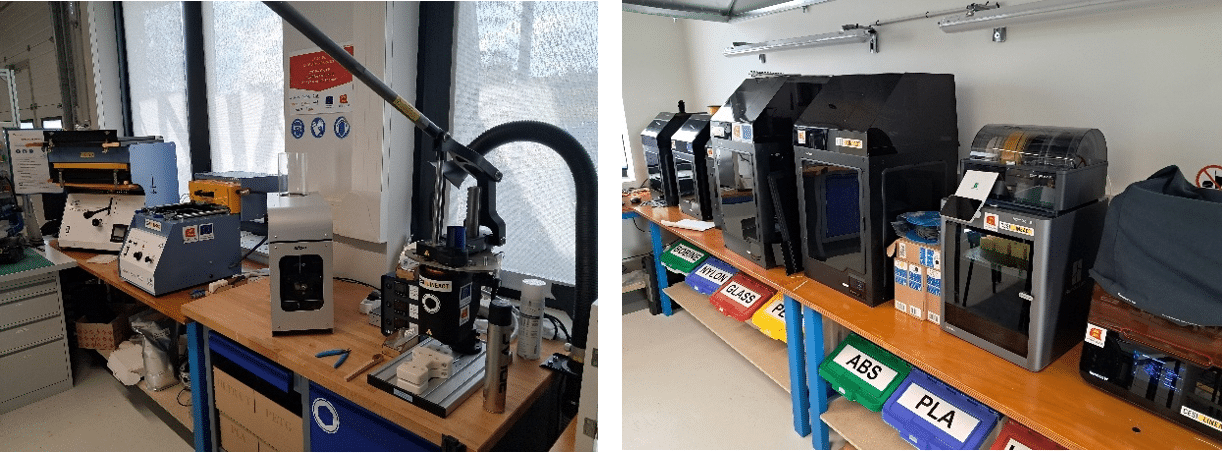

Action 2 – Building the Future : A Comprehensive Exploration of Object Manufacturing in a FabLab

The creative workshops offered in the FabLab for middle and high school students introduce them to modern manufacturing technologies and their industrial applications. Through an immersive approach, students discover the entire object manufacturing process, from CAD design to production using additive manufacturing, complemented by other techniques such as laser cutting, waterjet cutting, and finishing operations.

These workshops raise awareness of design challenges, material selection, recycling, and resource optimization, while developing skills in 3D modeling and digital fabrication. Adapted to students’ levels, the projects range from simple objects to more complex creations, fostering creativity, understanding of industrial technologies, and a hands-on approach to Industry 5.0.

Action 3 – Meeting the TIAGo Robot

Workshops centered on the TIAGo robot offer middle and high school students an immersive and playful introduction to programming and human–machine interaction through an intuitive graphical interface inspired by Scratch. Students learn to program the robot’s movements while discovering the fundamental principles of robotics.

A second interactive workshop takes the form of a voice-recognition quiz, during which students respond orally to questions asked by the robot. Through multimedia content, they discover the major contributions of women scientists throughout the history of science, fostering engagement, curiosity, and awareness of gender equality and the fight against stereotypes.

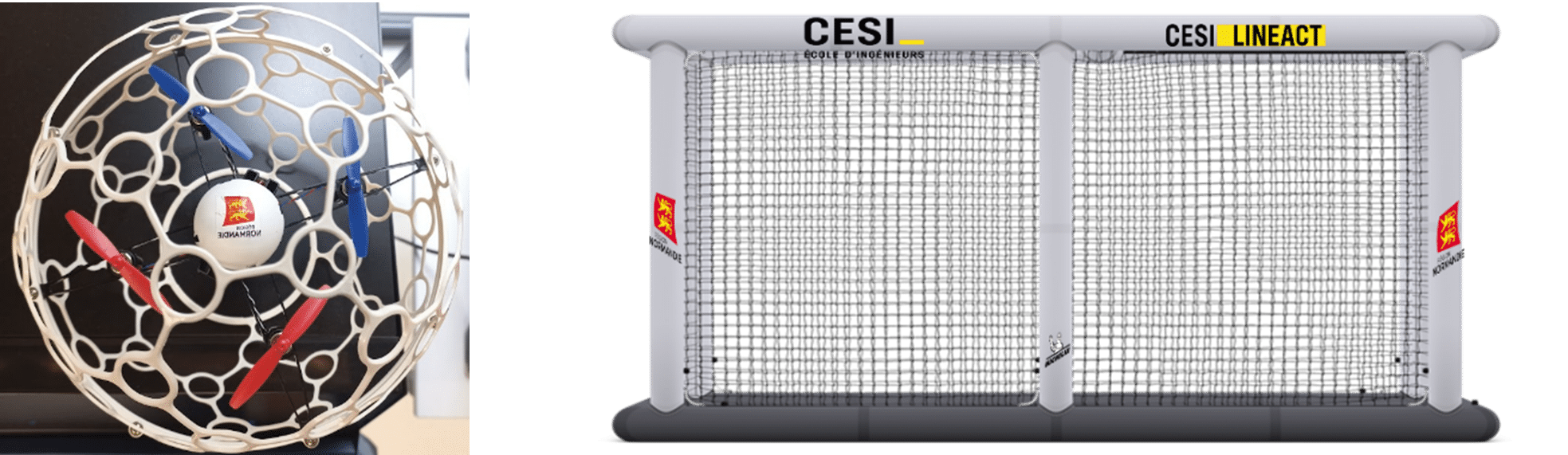

Action 4 – Using Drones to Explore Industry and Construction

The rapid development of drones in industry and construction represents a major technological advancement, particularly for inspection, monitoring, and mapping of complex sites. Their ability to access hard-to-reach areas and collect accurate data makes them essential tools for professionals.

A workshop dedicated to drones, designed for middle and high school students, will introduce them to this cutting-edge technology through a safe and supervised hands-on experience. Building on the research work of the LINEACT laboratory, particularly on collaboration between drones and ground robots, this workshop aims to spark students’ interest in science and innovative technologies.

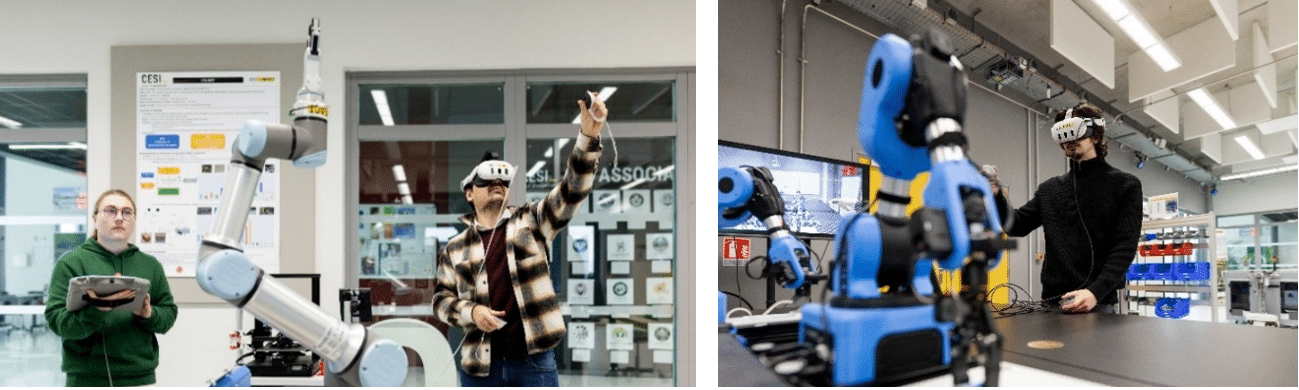

Action 5 – Immersive and Interactive Visits Through XR Digital Twins

This action offers an immersive experience centered on digital twins, enabling students to discover industrial applications of XR technologies (virtual, augmented and mixed reality). Using various immersive devices (XR headsets, CAVE systems), participants explore the operation and roles of industrial robots through interactive and educational scenarios. Simulation and potential connection to a real robot provide a concrete and in-depth understanding of the uses of XR and digital technologies in modern industry.

Achievements as of September 30, 2025:

Action 1 focused on developing interactive educational workshops around the UR16e robot, including a tic-tac-toe game, a maze, and a manipulation task based on artificial intelligence and camera vision. A logistics scenario was also implemented, combining a MiR mobile robot and a UR5 robot to automate tool distribution. In parallel, a complete software environment was designed, including URScript scripts for trajectory management, integration of the OnRobot gripper, communication modules such as OPC UA and SQL, a centralized RTDE system, a Python client, and web interfaces developed using HTML/CSS/JavaScript with Flask. Future perspectives include enhancing AI capabilities, developing a large-screen educational interface, and integrating new robots such as NIRYO.

Within the framework of Action 2, several improvements were made to the FabLab. The area dedicated to recycling was reorganized to ensure consistency with the 3D printing zone, while setup charts were created to standardize the use of the laser cutter and reduce errors. A Bambu Lab X1E 3D printer was acquired to strengthen educational activities thanks to its speed, versatility, and safety features. Official and internal maintenance procedures were implemented to improve the reliability and longevity of the equipment.

The Mobile FabLab was also redesigned into thematic zones : 3D printing, virtual reality, laser cutting, and recycling. The recycling module includes a shredder and a Holimaker injection press. This setup enabled numerous outreach activities in schools, as well as participation in events and forums.

Action 3 focused on the TIAGo robot through immersive workshops enabling middle and high school students to experiment with programming and human–robot interaction. Developments are currently underway to integrate new functionalities, particularly voice recognition, allowing direct dialogue with the robot. These activities raise young people’s awareness of artificial intelligence, natural language processing, and interactive systems.

As part of Action 4, programmable drone-soccer units using Scratch were deployed for educational purposes, with a request for twelve drones to enable up to twelve workshops to be run in parallel. The acquisition of a secure inflatable arena ensured safe flight conditions during the exercises. A professional DJI MAVIC 3E drone was also introduced to raise participants’ awareness of professional drone applications and the strict regulations governing their use.

Finally, Action 5 focused on the use of XR digital twins to explain industrial robotics and enable virtual manipulation of robots. The acquisition of the UBIK robot made it possible to simulate operations in hazardous areas, while the CESI platform, equipped with digital twins of robots such as NIRYO and UR, allows intuitive manipulation via a virtual gripper in mixed reality. These immersive workshops helped students better understand the challenges of Industry 5.0 and the new forms of human–robot collaboration.

All the actions carried out this year have significantly strengthened the dissemination of digital and robotic technologies among target audiences. Through interactive workshops, FabLab enhancements, the integration of collaborative robots, the use of drones, and XR digital twins, each initiative contributes to delivering innovative, accessible, and immersive learning experiences.

These initiatives foster understanding of the challenges of the industry of the future while stimulating creativity, curiosity, and active learning among participants. They therefore lay a solid foundation for the continued development of ever more modern and engaging tools and activities.