Optiman: Multi-objective optimization of robotic machining workshops focused on people and based on digital twins

- Partners: CESI, Ateliers Maugars.

- Call for projects: Support for collaborative innovation

- Overall project budget: €639k

- CESI project budget: €207k

- Project launch: October 1, 2023

- Project duration: 36 months

The OPTIMAN project aims to increase productivity in the production workshop by adopting an approach based on design optimization and the integration of robotic precision machining cells, followed by the optimization of product flows throughout the workshop. Industry 4.0 technologies and the concept of smart and sustainable factories will be used to supervise the cells and ensure their optimal operation, while integrating Industry 5.0 principles to place people at the center of systems and consider the well-being of operators in production workshops.

The three main objectives of the project are as follows:

i) Improve the operability of existing production tools:

- Reduce setup time per product and ensure continuous supply to machining cells.

- Develop solutions based on robotization and optimization of operation scheduling.

- Implement digital twins to monitor and control cells in real time.

ii) Optimize workshop operations:

- Develop an automatic decision-making tool for task and resource planning.

- Implement two levels of optimization: predictive and dynamic, to anticipate unforeseen variations during the execution of the predictive plan.

iii) Disseminate the results:

- Share results and best practices with other companies in the Normandy region through awareness workshops and the NAE network.

- Disseminate the work to the scientific community through national and international scientific publications.

Achievements as of March 31, 2025:

During this second year, the OPTIMAN project consolidated the foundations laid in 2024 and achieved several major technological and scientific milestones.

- Recruitment of a research engineer dedicated to the digital twin: his arrival enabled us to finalize the technical roadmap and streamline exchanges with Les Ateliers Maugars.

- Integration of a Master’s research intern tasked with exploring human-centered scheduling, whose initial experiments are already feeding into our applied research pipeline.

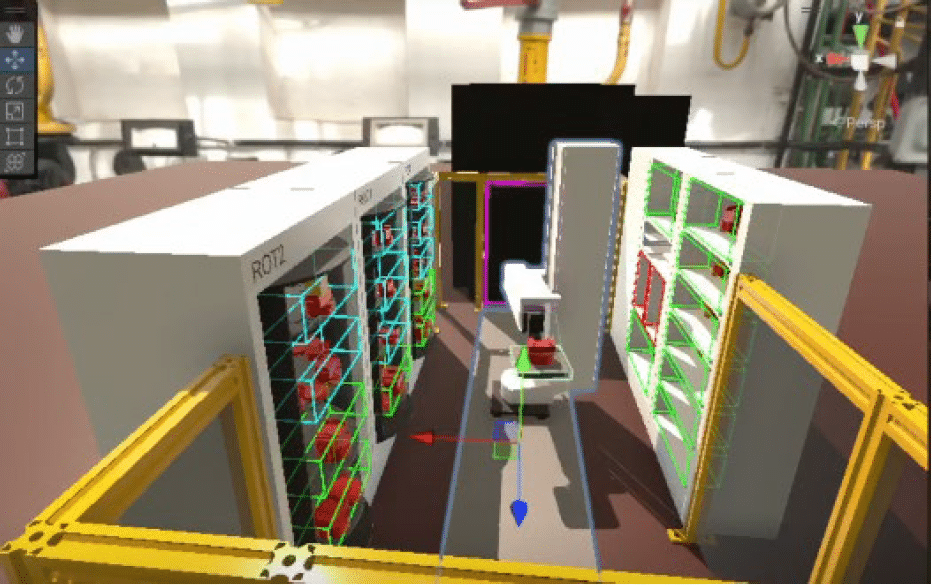

- Production of the first fully operational digital twin for the robotic cell: 3D modeling, real-time connection to sensors, and visualization of performance indicators (cycle time, energy consumption).

- Collection and structuring of industrial data (production orders, machine parameters, sensor histories) in a unified database, an essential condition for automatic scheduling.

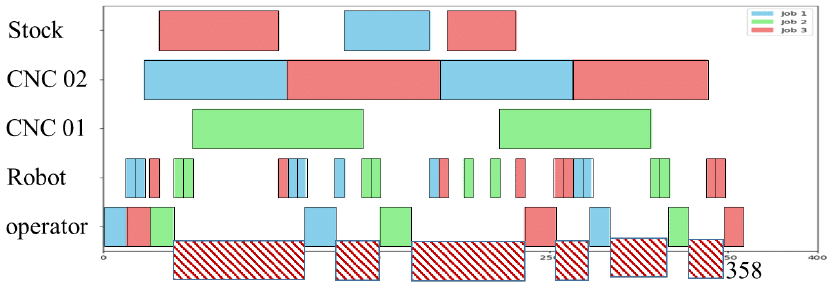

- Deployment of an initial task scheduling engine capable of generating optimized sequences based on load and resource availability.

- Collection and structuring of industrial data (production orders, machine parameters, sensor histories) in a unified database, an essential condition for automatic scheduling.

- Deployment of an initial task scheduling engine capable of generating optimized sequences based on workload and resource availability.

- Development of a prototype for genetic optimization of cell configuration (workstation layout, buffers, robot trajectories): the multi-objective evolutionary algorithm, coupled with the digital twin, virtually evaluates hundreds of variants and selects the Pareto-optimal solutions.

- Publication of an article accepted at the IEEE AFROS 2024 conference presenting the methodology for coupling digital twins and genetic optimization for flexible production systems, enhancing the project’s visibility in the scientific community.

- Launch of recruitment for a second research engineer to take over the work of optimizing production tasks on the robotic cell.

These advances demonstrate the increasing maturity of the solutions developed and illustrate the synergy between academic research and industrial needs, paving the way for the pilot commissioning of the optimized robotic cell in 2025.